Definitions

Operating temperatures for DURBAL Premium-, Classic-, Basic-Line

–

Bearing: Antifriction bearing

Temperature range: -45° C to +120° C

Bearing: Polyamide PTFE glass fibre compound

Temperature range: -30° C to +60° C

Bearing: Steel / Brass

Temperature range: -40° C to +110° C

Bearing: Steel / PTFE

Temperature range: -40° C to +200° C

Bearing: Steel / PTFE with -2RS

Temperature range: -40° C to +120° C

Bearing: Steel / Steel

Temperature range: -40° C to +200° C

Bearing: Steel / Steel with -2RS

Temperature range: -40° C to +120° C

A loss in load rating capacity occures at higher temperatures, which must be accounted for in the operating life estimate with the temperature factor C2.

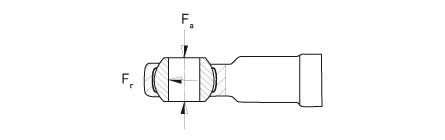

Loads

–

The decisive parameters for the selection and calculation of DURBAL heavy-duty rod ends and spherical plain bearings are size, direction and type of load.

Radial and combined loads

–

The DURBAL heavy-duty The DURBAL heavy-duty rod ends and spherical plain bearings have been especially designed to adopt high radial loads Fr. They can furthermore be used for combined loads. The axial load share Fa of which does not exceed 20% of the corresponding radial load.

Unilaterally acting load

–

In this case the load acts only in the same direction, which means that the load area is always in the same bearing section.

Alternately acting load

–

In case of alternating loads, the load areas facing each other are alternately loaded and/or relieved, which means that the load changes its direction constantly by approx. 180°.

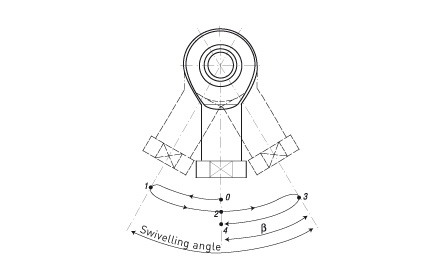

Swivelling angle

–

The swivelling angle is the excursion of the rod end from one final position to the other. Half the swivelling angle β is used to calculate the working life.

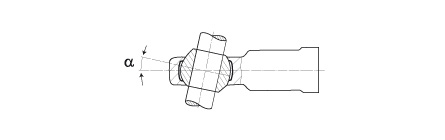

Tilt angle

–

The tilt angle refers to the possible excursion of the joint ball and/or the inner ring to the rod end axis in degrees. The tilt angle α indicated in the table corresponds to the maximum possible excursion. It is important that this tilt angle is not exceeded either during installation or operation.

Working life

–

The term >working life< is used with rod ends respectively with spherical-plain bearings. It represents the number of swivelling motions or rotations and/or the number of service hours the rod ends/spherical-plain bearings perform before becoming unserviceable because of material fatigue, wear, increased bearing clearance or increase of the bearing friction moment. The working life is not only influenced by the size and the type of load, it is also affected by a number of factors, which are partially difficult to assess. A calculation of the exact service life is therefore impossible. Field experienced standard values for the approximate working life can nevertheless be determined by using the following calculation procedure which is based on numerous results from endurance test runs and values from decades of experience.

The values determined by this formula are achieved, normally even exceeded, by the majority of the DURBAL heavy-duty rod ends and spherical-plain bearings. The specific loading of rod ends and spherical-plain bearings differs in each application. Therefore general statements by a producer in a catalog may not totally fit to the single application. In all cases the user has to coordinate the theoretical selection criteria with the concrete installation situation and check the suitability of the rod end respectively spherical-plain bearing. In this context the user has to define sufficient security factors and maintenance intervals.

DURBAL Definitions – Operating temperatures, Loads, Unilaterally acting load, Alternately acting load, Swivelling angle, Tilt angle, Working life.

We will answer you asap

> info@durbal.de

You can reach us under the phone number

> +49 (0) 7941 9460-0